main features

1. Efficient and energy-saving: Adopting a three-dimensional structure design, it occupies a small area and has low energy consumption.

2. Uniform particle size: The finished product particle size can be adjusted between 80-325 mesh, with a uniform particle size distribution.

3. High degree of automation: equipped with an electrical control system, easy to operate, and capable of achieving automated operation.

4. Strong durability: Key components are made of high-quality materials, with good wear resistance and long service life.

5. Good environmental performance: equipped with dust removal equipment, low dust emissions, in line with environmental requirements.

Working principle

1. Feeding: The material is evenly fed into the powder mill through a feeder.

2. Grinding: The material is crushed and ground between the grinding roller and the grinding ring, gradually turning into fine powder.

3. Grading: The ground material is graded by a classifier, and materials that meet the particle size requirements are collected. Materials that do not meet the requirements are returned for further grinding.

4. Collection: The finished powder is collected through a cyclone collector or pulse dust collector.

application area

1. Building materials industry: used for grinding minerals such as limestone, gypsum, talc, etc.

2. Chemical industry: used for grinding and processing of chemical raw materials.

3. Metallurgical industry: used for grinding and beneficiation of ores.

4. Mining industry: used for grinding and processing non-metallic minerals.

5. Other fields: used in industries such as ceramics, glass, refractory materials, etc.

Choose Suggestions

1. Material characteristics: Select the appropriate model based on the hardness, humidity, and particle size of the material.

2. Capacity demand: Select equipment specifications and power based on production scale.

3. Finished product particle size: Select the appropriate classifier according to the requirements of finished product particle size.

4. Brand and after-sales service: Choose a reputable brand to ensure after-sales service.

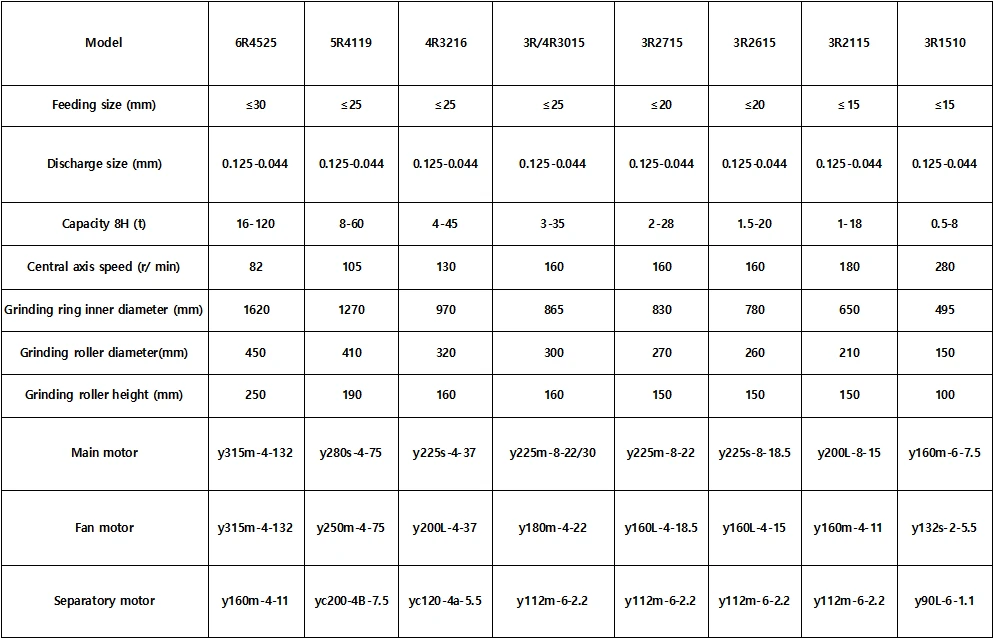

Technical Parameter

maintenance

1. Regular lubrication: Regularly lubricate moving parts such as bearings and gears to reduce wear.

2. Check the grinding rollers and rings: Regularly inspect the wear of the grinding rollers and rings and replace them in a timely manner.

3. Cleaning equipment: Regularly clean the residual materials inside the equipment to prevent blockage.

4. Check the electrical system: Regularly inspect the electrical system to ensure safe operation of the equipment.

5. Maintenance of dust removal equipment: Regularly clean and maintain dust removal equipment to ensure environmental performance.

Common faults and solutions

1. Decreased production: Check the wear of the grinding rollers and rings and replace them in a timely manner.

2. The finished particles are too coarse: adjust the speed of the classifier or check the wear of the classifier.

3. Abnormal equipment vibration: Check if the bolts are loose and adjust the equipment balance.

4. Overheating of bearings: Check the lubrication condition and replenish or replace the lubricating oil.