Main features

1. Efficient drying: The drum design ensures full contact between the material and hot air, resulting in fast drying speed.

2. Uniform heating: The rotation of the drum ensures uniform heating of the material, avoiding local overheating or insufficient drying.

3. Strong adaptability: can handle various materials, such as particles, powders, blocks, etc.

4. Easy to operate: high degree of automation, easy to control temperature and humidity.

5. Energy saving and environmental protection: Adopting a hot air circulation system to reduce energy waste.

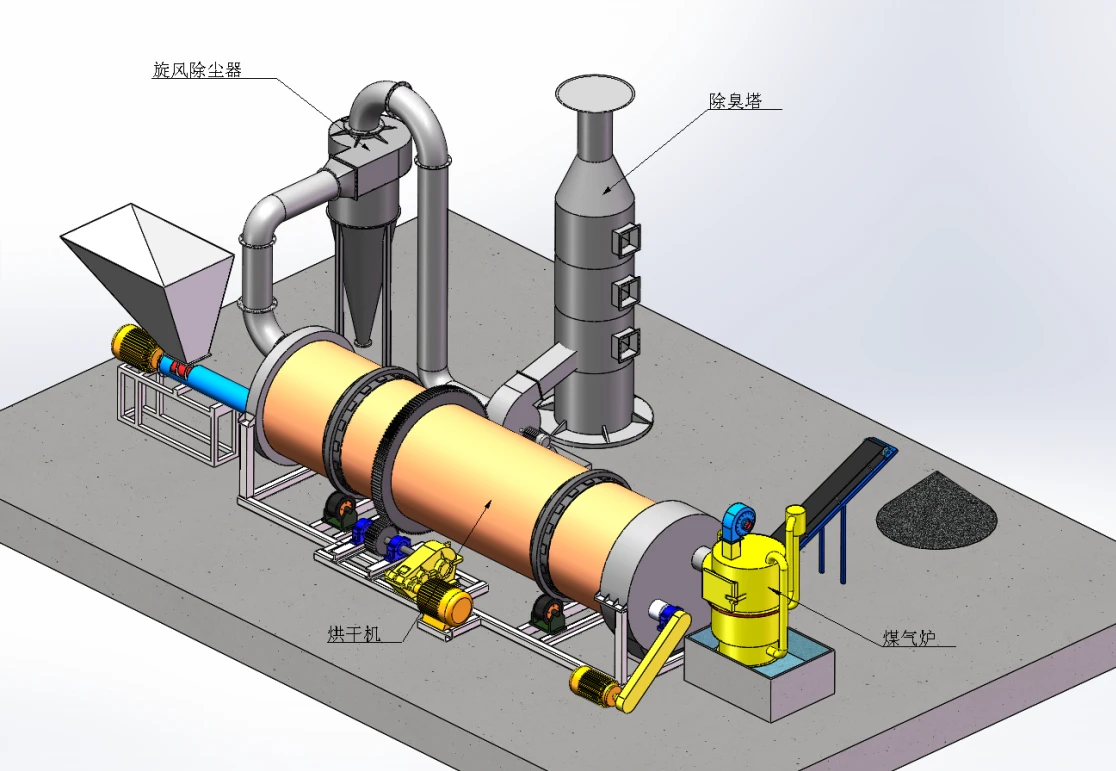

Working principle

1. Feed: Wet materials enter the drum through the feed inlet.

2. Heating: A hot air stove or electric heating system generates hot air that passes through the interior of the drum.

3. Rotary drying: The drum rotates slowly, and the material keeps flipping inside the drum, fully contacting the hot air.

4. Moisture removal: Moisture is discharged through the moisture removal system to keep the drum dry.

5. Discharge: The dried material is discharged from the discharge port.

Application area

1. Agriculture: Drying grains, corn, soybeans, feed, etc.

2. Food processing: drying vegetables, fruits, nuts, tea leaves, etc.

3. Chemical industry: drying chemical raw materials, minerals, fertilizers, etc.

4. Building materials: drying sand, slag, clay, etc.

5. Textile: Drying textiles, yarns, etc.

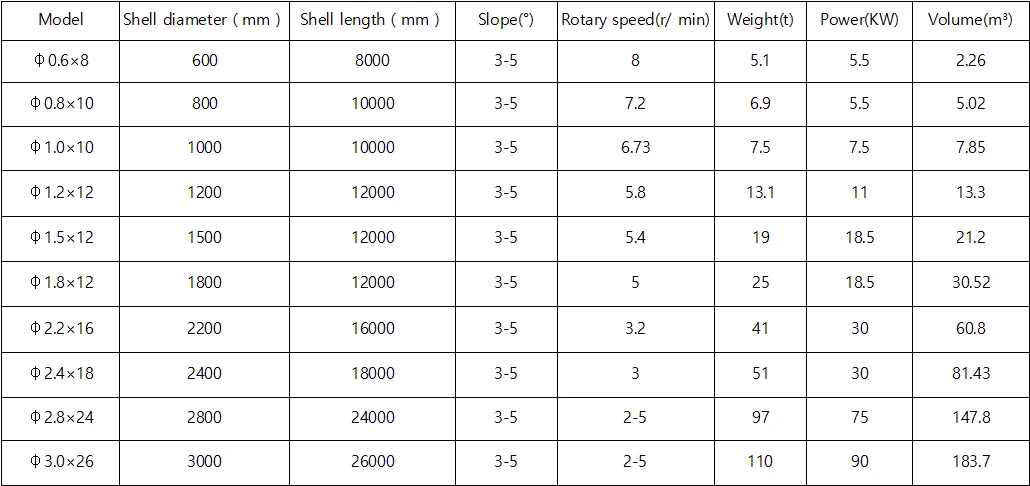

Technical Parameter

Maintenance

1. Regular cleaning: Clean the residual materials inside the drum to prevent blockage.

2. Check the drum: Regularly check the wear of the drum and repair or replace it in a timely manner.

3. Lubrication and maintenance: Regularly lubricate moving parts such as bearings and gears to reduce wear and tear.

4. Check the hot air system: Ensure that the hot air stove or heater is working properly, and clean the hot air duct.

5. Electrical inspection: Regularly inspect the electrical system to ensure safe operation of the equipment.