Main Features

1. Flexible mobility: Equipped with tires or track chassis, it can quickly transfer between different work sites.

2. Integrated design: integrating functions such as feeding, crushing, screening, and conveying, reducing equipment configuration and installation time.

3. Strong adaptability: Suitable for complex terrains and various materials, such as rocks, ores, construction waste, etc.

4. Efficient and energy-saving: Adopting advanced crushing technology and energy-saving design to reduce operating costs.

5. High degree of automation: equipped with an intelligent control system, easy to operate, and capable of achieving automated operation.

Working Principle

1. Feeding: The material is evenly fed into the crushing equipment through a feeder.

2. Crushing: Materials are crushed in crushing equipment such as jaw crushers, cone crushers, impact crushers, etc.

3. Screening: The crushed materials are classified by screening equipment. Materials that meet the particle size requirements are directly output, while those that do not meet the requirements are returned to the crushing equipment for further crushing.

4. Conveyor: Finished materials are transported to designated locations by conveyor belts.

Application Area

1. Mining industry: Used for ore crushing and screening in open-pit mines.

2. Construction industry: used for the recycling and reuse of construction waste.

3. Highway and railway: used for crushing and screening roadbed materials.

4. Water conservancy engineering: used for the production of sand and gravel aggregates.

5. Other fields: used for urban demolition, solid waste treatment, etc.

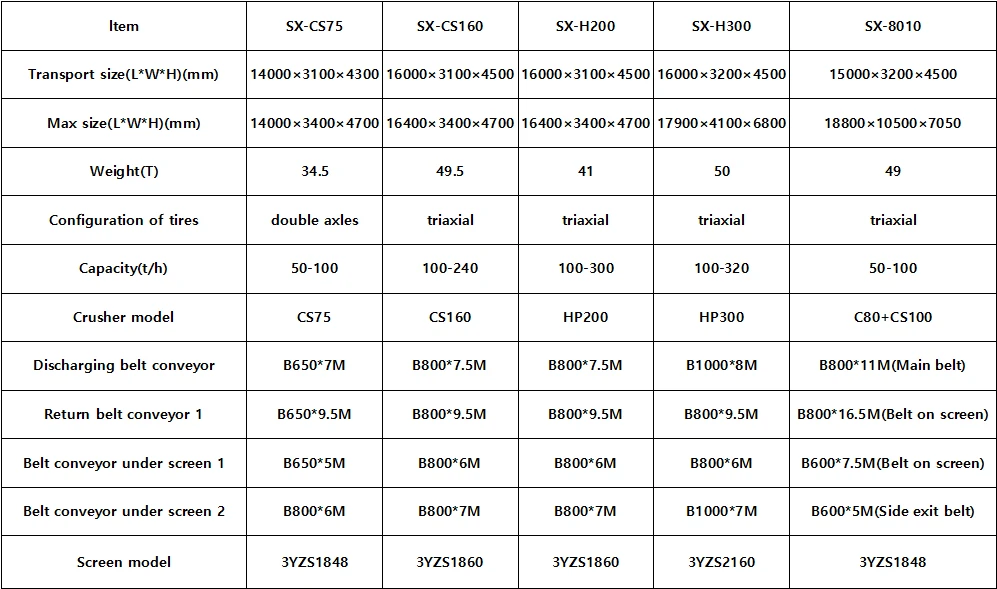

Technical Parameter

Maintenance

1. Regular lubrication: Regularly lubricate moving parts such as bearings and chains to reduce wear.

2. Check vulnerable parts: Regularly inspect the wear of vulnerable parts such as lining plates and screens of crushing equipment, and replace them in a timely manner.

3. Tighten bolts: Regularly check and tighten the bolts of various parts of the equipment to prevent loosening.

4. Cleaning equipment: Regularly clean the residual materials inside the equipment to prevent blockage.

5. Electrical inspection: Regularly inspect the electrical system to ensure safe operation of the equipment.

Common faults and solutions

1. The device cannot start: Check the power and control system to troubleshoot.

2. Low crushing efficiency: Check the wear and tear of the crushing equipment and replace vulnerable parts in a timely manner.

3. Poor screening effect: Check whether the screen mesh is blocked or worn, and clean or replace it in a timely manner.

4. Conveyor belt deviation: Adjust the tension and position of the conveyor belt to ensure normal operation.