Main features

1. Simple structure: compact design, easy to install and maintain.

2. Efficient crushing: High crushing ratio and high production efficiency.

3. Strong adaptability: It can handle materials of various hardness, such as granite, basalt, ore, etc.

4. Strong durability: Key components are made of high-strength materials, with good wear resistance and long service life.

5. Easy to operate: high degree of automation, stable operation.

Working principle

1. Feed: The material enters the crushing chamber from the feed inlet.

2. Squeezing and crushing: The moving jaw plate moves periodically under the drive of the eccentric shaft, and squeezes the material when it approaches the fixed jaw plate.

3. Discharge: The crushed material is discharged from the discharge port, and the particle size is controlled by the gap between the discharge ports.

Application area

1. Mining industry: crushing iron ore, copper ore, gold ore, etc.

2. Building materials industry: crushed limestone, granite, basalt, etc.

3. Metallurgical industry: crushing slag, scrap steel, etc.

4. Chemical industry: crushing chemical raw materials.

5. Other fields: Used for laboratory sample crushing or coarse crushing in small production lines.

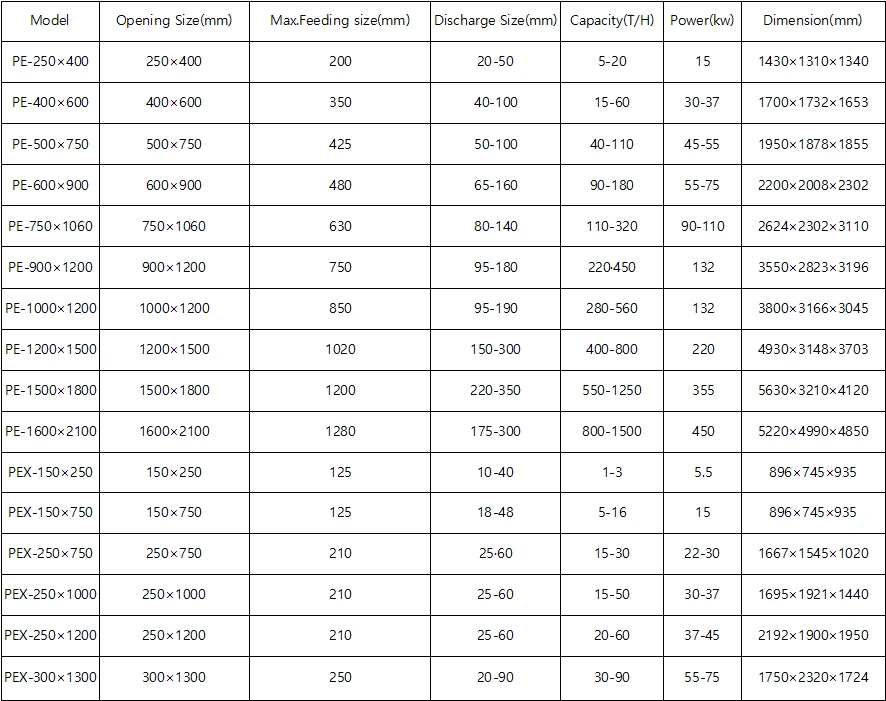

Technical Parameter

Maintenance

1. Regular lubrication: Regularly lubricate moving parts such as bearings and eccentric shafts to reduce wear.

2. Check the jaw plate: Regularly inspect the wear of the jaw plate and replace it in a timely manner.

3. Tighten bolts: Regularly check and tighten the bolts of various parts of the equipment to prevent loosening.

4. Cleaning the crushing chamber: Regularly clean the residual materials inside the crushing chamber to prevent blockage.

5. Electrical inspection: Regularly inspect the electrical system to ensure safe operation of the equipment.

Common faults and solutions

1. Jaw plate wear: Replace with a new jaw plate.

2. Overheating of bearings: Check the lubrication condition and replenish or replace the lubricating oil.

3. Abnormal equipment vibration: Check if the bolts are loose and adjust the equipment balance.

4. Uneven discharge particle size: Adjust the clearance between the discharge port or check the wear of the jaw plate.