Main features:

1. Efficient dehumidification: Designed for high humidity materials, it can quickly remove a large amount of moisture and improve drying efficiency.

2. Temperature control: Adopting an intelligent temperature control system, the drying temperature can be adjusted according to the characteristics of the material to avoid overheating or insufficient drying.

3. Energy saving and environmental protection: Adopting a hot air circulation system to reduce heat loss, lower energy consumption, and meet environmental protection requirements.

4. Uniform drying: By designing a reasonable distribution of hot air, the material is heated evenly, avoiding local overheating or uneven drying.

5. Multifunctionality: Suitable for various high humidity materials, such as grains, fruits and vegetables, sludge, wood, etc.

6. Automated operation: Equipped with PLC control system to achieve automated operation and reduce manual intervention.

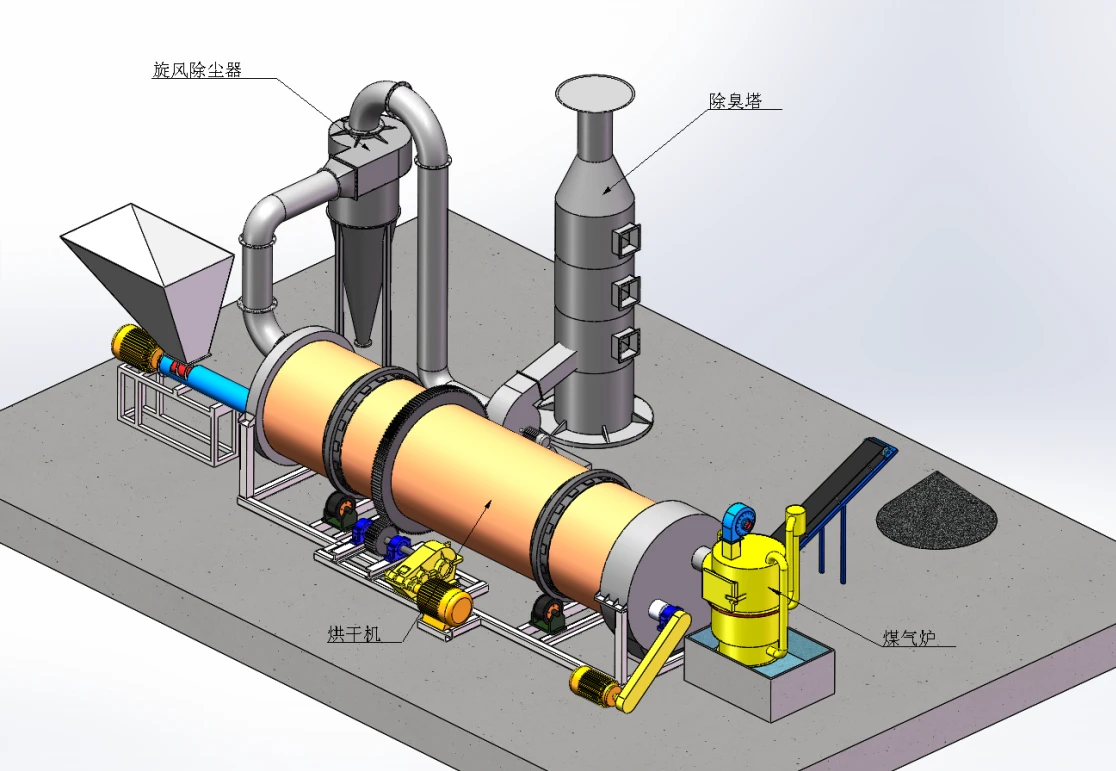

working principle:

High humidity dryers usually use the working principle of hot air circulation:

1. Heating system: Generate hot air through methods such as electric heating, steam heating, or gas heating.

2. Hot air circulation: Hot air circulates in the drying room, coming into contact with high humidity materials and removing moisture from the materials.

3. Humidity discharge: Moisture is discharged from the dryer through the dehumidification system to maintain humidity balance in the drying room.

4. Cooling discharge: After drying, the material is cooled down by the cooling system and discharged to ensure the quality of the material.

5. Preventing adhesion: Rotating devices, chain plates, chains, and other tapping devices are installed inside the drying drum to prevent adhesion of high humidity materials.

Application areas:

1. Food industry: used for drying high humidity food raw materials such as fruits, vegetables, grains, tea, and medicinal herbs.

2. Chemical industry: used for drying high humidity materials such as chemical raw materials, sludge, fertilizers, etc.

3. Agricultural field: used for drying agricultural products such as grains, feed, straw, etc.

4. Wood processing: used for drying high humidity raw materials such as wood and bamboo.

5. Environmental protection industry: used for treating high humidity waste such as sludge and biomass.

Maintenance and upkeep:

1. Regular cleaning: Clean the residual materials inside the dryer to prevent blockage and contamination.

2. Check the heating system: Regularly inspect the heating elements (such as electric heating tubes, burners, etc.) to ensure their normal operation.

3. Lubricate moving parts: lubricate moving parts such as fans and conveyor belts to reduce wear and tear.

4. Check sealing: Ensure good sealing of the dryer to avoid heat loss.

5. Regularly calibrate the temperature control system: ensure accurate temperature control and avoid excessive or insufficient drying.