1、 Core mechanical action:

Impact crushing

When the cylinder rotates, the grinding medium (such as steel balls) is carried to a certain height by centrifugal force and falls freely, generating high-speed impact force and crushing large particle materials.

Critical speed: When the rotational speed of the cylinder reaches the speed that causes the medium to centrifuge and adhere to the wall (75% -88% of the critical speed is the optimal working speed), the impact force is at its maximum.

Grinding refinement

When the medium rolls or slides with the cylinder, the material is squeezed and ground in the gap between the media, especially suitable for hard and brittle materials such as ores and ceramics.

Wet assisted: In a wet ball mill, liquid (such as water) infiltrates into the gaps between particles, reducing surface energy and improving grinding efficiency.

Friction and Shear

The friction between materials, media, and cylinder liners further refines the particles, especially in the fine grinding chamber (flat liner area).

2、 Key working parameters:

Parameter Function and Influence

The rotational speed determines the motion mode of the medium: too low (mainly sliding), moderate (throwing impact), too high (centrifugal failure)

The filling ratio of the medium to the cylinder volume (usually 25% -45%) is too high, which leads to a decrease in impact energy, and too low, which reduces grinding efficiency

Medium ratio: large ball (coarse grinding), small ball (fine grinding), multi-stage ratio optimization crushing gradient

The slurry concentration in the wet ball mill affects the flowability, and excessive concentration leads to the "slurry coating" effect of the grinding medium.

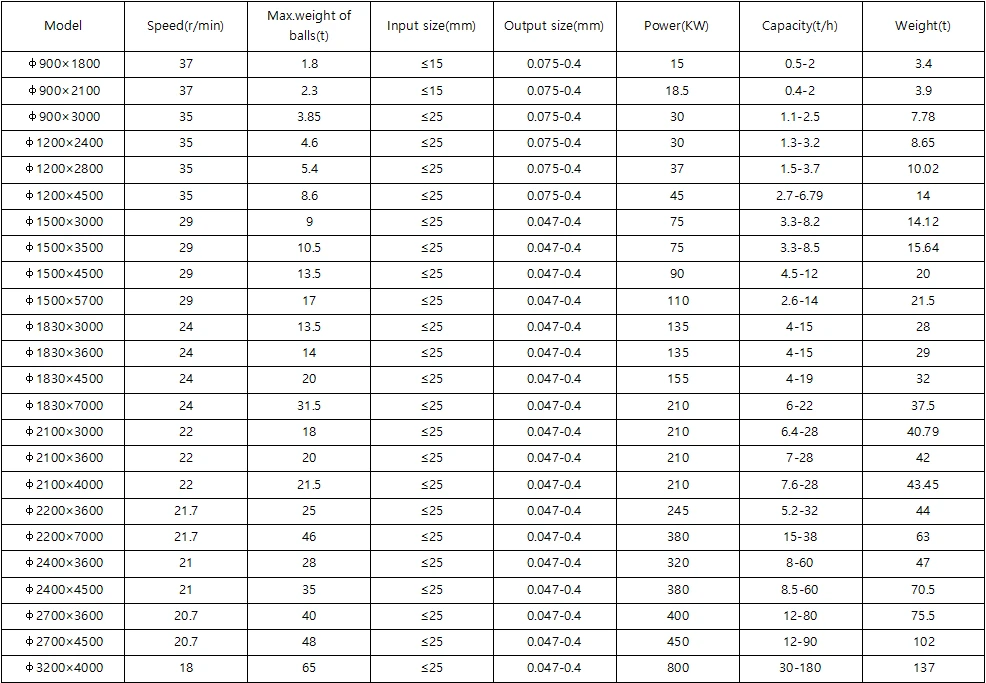

3.Technical Parameter