Core technological advantages:

1. Efficient and energy-saving: The three tube design improves thermal efficiency, shortens drying time, and reduces energy consumption.

2. Independent control: Each drum can be operated independently, suitable for processing multiple materials simultaneously.

3. Uniform drying: The drum design ensures that the material is heated evenly, avoiding local overheating or insufficient heating.

4. Large capacity: suitable for large-scale production, improving efficiency.

5. Structural innovation: Three tube nested layout reduces equipment volume and occupies more than 30% of the floor area; The combination detachable patented design supports modular disassembly and assembly, solving the problem of traditional three cylinder machine maintenance.

6. Strong durability: Made of high temperature and corrosion-resistant materials to extend the service life.

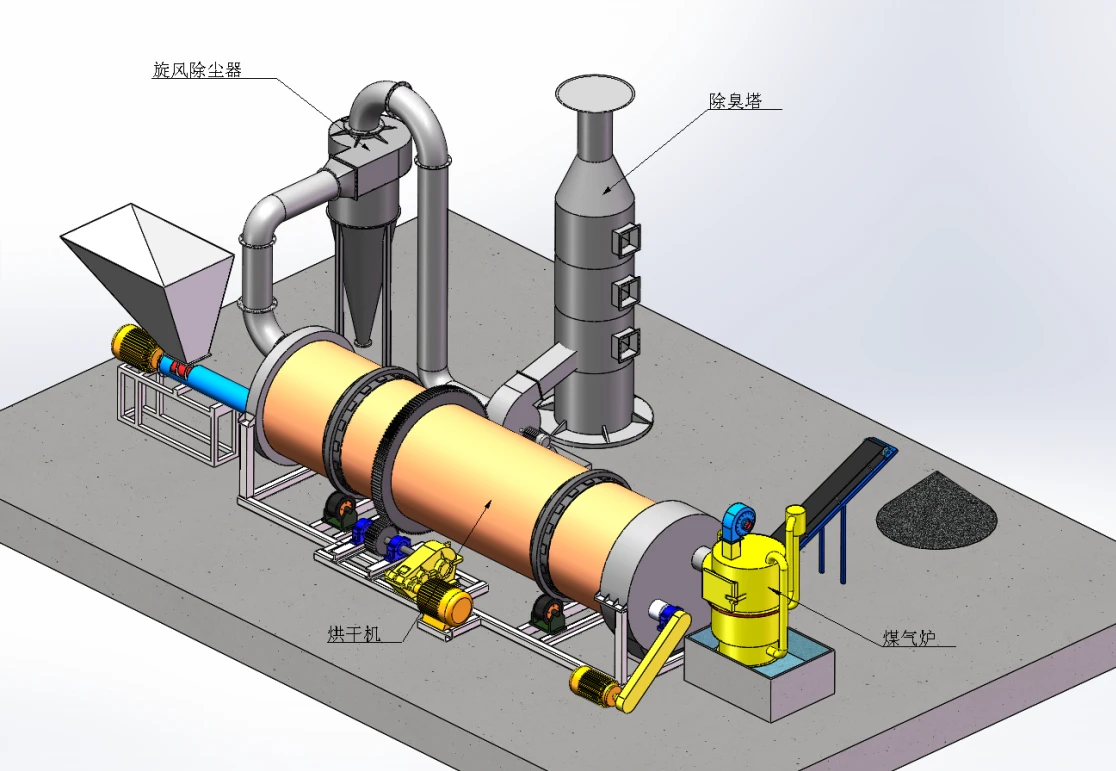

7. Intelligent control: equipped with a variable frequency speed regulation system, which can adjust the speed according to the moisture content of the material and adapt to different production needs; Automatic temperature monitoring and dust removal device (cyclone+bag type) achieve environmental compliance.

application area:

1. Agriculture: Drying grains, feed, tea, etc.

2. Food processing: drying vegetables, fruits, nuts, etc.

3. Chemical industry: drying chemical raw materials, minerals, etc.

4. Textile: Drying textiles, yarns, etc.

5. Wood processing: drying wood, sawdust, etc.

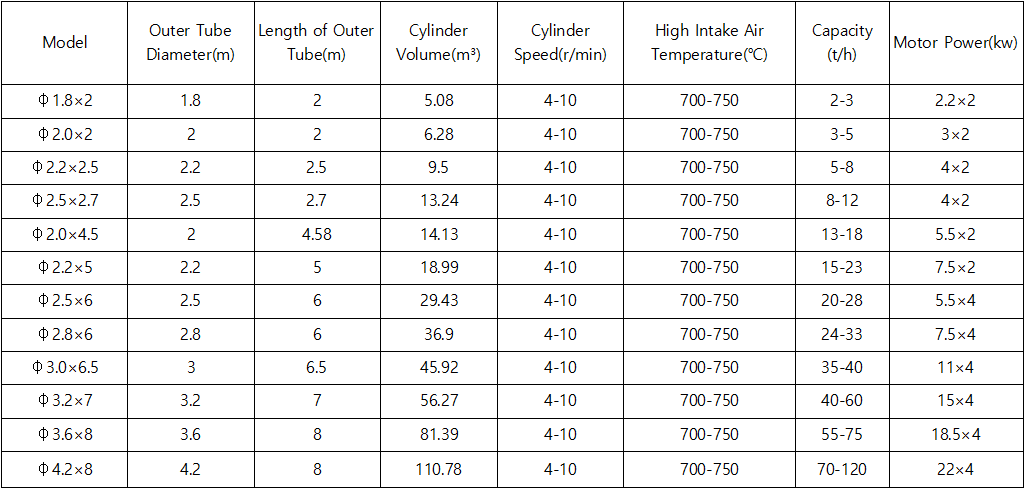

Technical Parameter

maintenance:

1. Regular cleaning: prevent material residue from affecting efficiency.

2. Check the drum: Regularly inspect for wear and replace it in a timely manner.

3. Lubrication and maintenance: Regularly lubricate moving parts to reduce wear and tear.

4. Electrical inspection: Regularly inspect the electrical system to ensure safe operation.